RFID Technology Leads Innovation in the Automotive Industry

- Share

- Issue Time

- Nov 19,2024

Summary

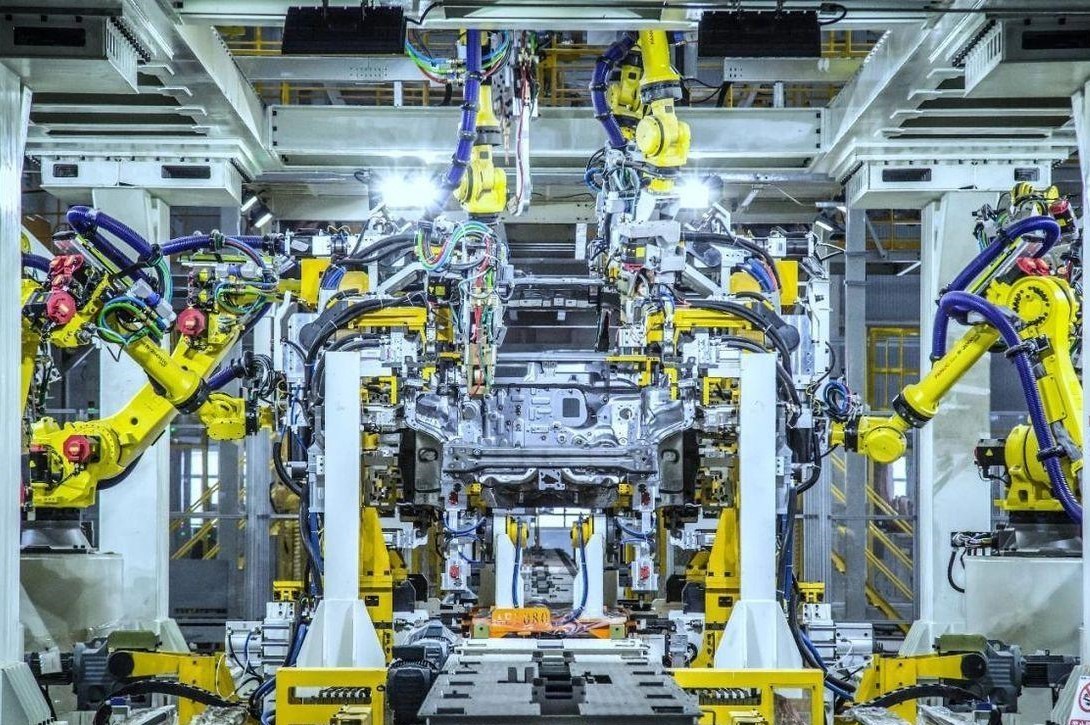

With the continuous development of the Internet of Things technology, RFID (Radio Frequency Identification) technology has increasingly been applied in the automotive industry, bringing revolutionary changes to automakers and component suppliers. From production line monitoring to inventory management, logistics optimization, and security enhancement, RFID technology has demonstrated its immense potential.

In recent years, the application of RFID technology in the automotive industry has achieved remarkable results, becoming an important force driving change in the sector. As an automatic identification technology that does not require human intervention, RFID collects relevant data about target objects through radio signals. Its electronic tags and reader systems enable real-time tracking of automotive components and raw materials, ensuring smooth operation of production lines.

In the automotive manufacturing sector, RFID technology is primarily used for component tracking, production line monitoring, inventory management, logistics optimization, and security enhancement. On the production line, RFID technology can track the location of automotive components in real-time. If a component is lost or delayed, the system can immediately issue an alert, helping management quickly locate the issue, thus avoiding production interruptions and delays. This real-time tracking capability not only improves production efficiency but also significantly reduces production costs.

In terms of quality control, RFID tags can carry product information such as production dates and specifications. By continuously collecting data during the production process, RFID technology can help the quality control department promptly detect abnormalities, ensuring product quality. This is undoubtedly a huge boon for the automotive manufacturing industry, which has extremely high quality requirements.

In inventory management, RFID systems can track the location and quantity of inventory items in real-time, reducing human errors and improving the accuracy and efficiency of inventory management. This means automakers can more accurately grasp the inventory situation of raw materials and components, thereby making more reasonable procurement and production plans.

In logistics, the introduction of RFID technology has brought a qualitative leap in efficiency improvement. Through the reading of RFID tags by readers, automated collection and transmission of logistics information can be achieved, greatly improving logistics efficiency and reducing costs. Especially in the warehousing, transportation, and distribution processes of components, RFID technology can realize real-time logistics tracking and vehicle status monitoring, making the entire logistics process more transparent and controllable.

Apart from efficiency improvements, RFID technology has also played an important role in enhancing security in the automotive industry. RFID tags can contain unique anti-counterfeiting codes for product authentication. Meanwhile, installing RFID anti-theft devices on vehicles can monitor the real-time location and status of the vehicle, effectively preventing theft or other security issues. This increase in security not only protects corporate assets but also enhances consumer trust.

It is worth noting that RFID technology has not only demonstrated its potential in automotive manufacturing and logistics but has also sparked digital transformation in tire service industries. For example, the V788 balancer released by Italian tire rotation service equipment company Fasep is the world's first wheel balancer integrated with an RFID tag reading system. This technology can automatically identify tires with RFID tags, enabling immediate acquisition of tire data and instant communication with operators, bringing unprecedented convenience and accuracy to tire identification, management, and service.

In summary, the application of RFID technology in the automotive industry has achieved remarkable results, not only improving production efficiency, optimizing inventory management, enhancing logistics efficiency, but also strengthening product security and anti-counterfeiting capabilities. With continuous technological development and improvement, RFID technology will play an even more important role in the automotive industry, leading it towards a more efficient, intelligent, and secure future.