RFID Intelligent Warehousing And Logistics Solutions

- Share

- Issue Time

- Mar 14,2023

Summary

Use RFID technology for inbound, outbound and warehouse management, not only greatly saves manpower and material resources, so that the efficiency has been greatly enhanced, more importantly, it achieves the dynamic control of the enterprise for the supply chain, in the competitive market environment in advance to take advantage and a head start.

Faced with the huge market competition and pressure in the field of warehousing and logistics nowadays, how to build the core competitiveness of industrial enterprises by improving efficiency becomes a problem for managers to think about. RFID technology can largely enhance the efficiency level of modern warehousing and logistics, therefore, the establishment of RFID intelligent warehousing and logistics system is essential.

The traditional warehouse logistics "pure manual mode", facing the following problems.

1 "manual piecework" resulting in statistical accuracy problems, will cause unnecessary economic losses.

2 "manual filling" resulting in leakage, errors, chaos and other problems, will seriously affect the accuracy and timeliness of warehousing and logistics distribution.

3 "Manual inventory" way time-consuming and labor-intensive, and the risk of rework.

4 "Labor cost" rising problem, leading to increasing operating costs.

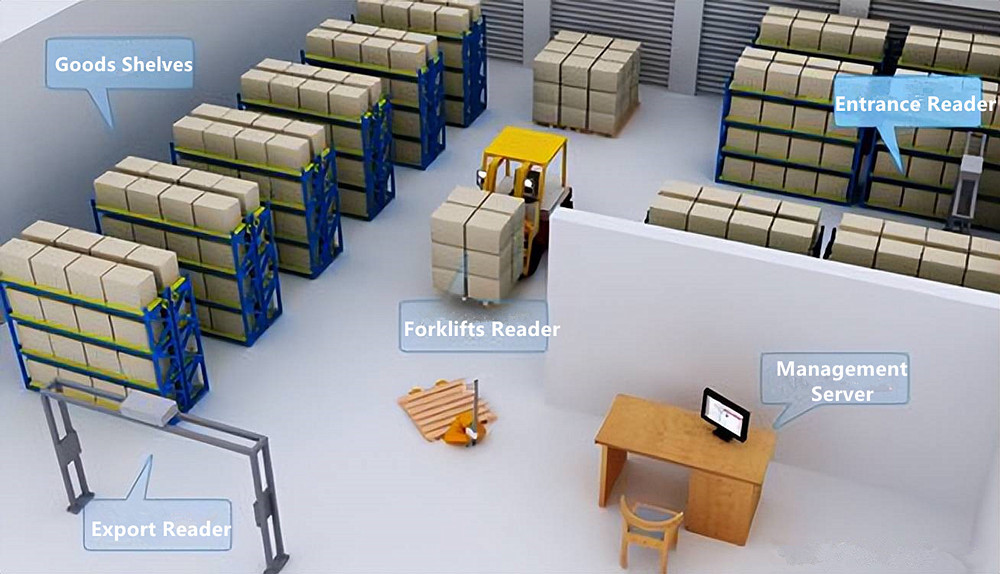

RFID in intelligent logistics warehousing in three common scenarios

Intake management

When the goods into the warehouse door, RFID access door or door around the fixed reader will read the goods tag information, while the corresponding cargo information sent to the loading and unloading terminal. When the loading and unloading truck arrives at the designated cargo position, the fixed reader on the loading and unloading truck reads the cargo label information and puts the goods on the designated cargo position.

The whole process of goods warehousing, loading and unloading truck on the goods information, will automatically, real-time update to the RFID inventory management system. At the time of warehousing, it is also possible to rationalize the cargo position selection through the system.

Out of storage management

When leaving the warehouse, the RFID outbound management system will notify the warehouse management personnel to leave the warehouse and ship the goods according to the principle of first-in-first-out. The system will automatically prompt the car computer shows the location of the goods, loading and unloading car operators according to the path to reach the corresponding shelves. RFID reading and writing equipment of the loading and unloading car will again confirm whether the goods taken are correct, and at the same time update the inventory of goods.

Inventory management

Daily inventory count, you can scan the goods by RFID handheld machine, and at the same time compare with the inventory information in the database for confirmation. In addition, the goods can also be updated to the database in real time through RFID handheld devices when they are shifted.

Using RFID technology for inventory management, we can accurately grasp inventory information in real time and improve inventory management capabilities.

Overall, the use of RFID technology for inbound, outbound and warehouse management, not only greatly saves manpower and material resources, so that the efficiency has been greatly enhanced, more importantly, it achieves the dynamic control of the enterprise for the supply chain, in the competitive market environment in advance to take advantage and a head start.