RFID Technology for Fast Retailing -- Uniqlo

- Share

- Issue Time

- Mar 2,2023

Summary

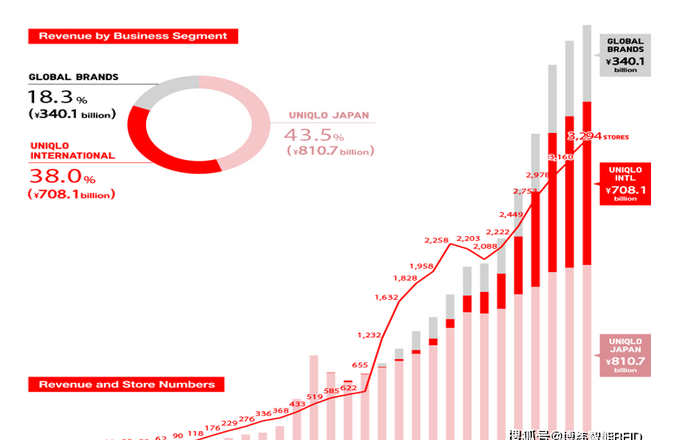

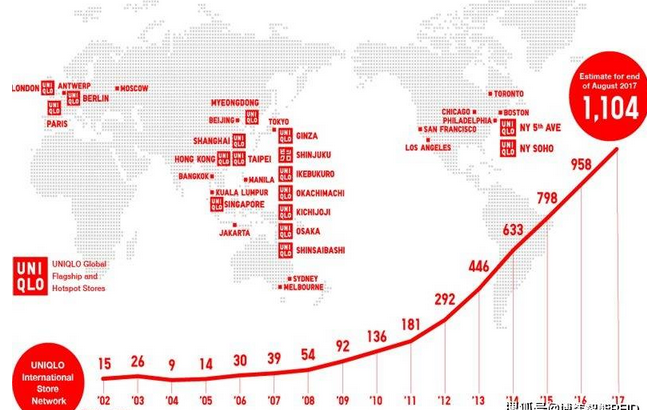

There are more and more fashion clothes giant like H&M , Zara,and UNIQLO applied RFID technology nowadays. At the beginning of 2019, the parent company of Uniqlo, Fast Retailing, announced that it would carry out RFID label reform in 3000 stores worldwide. Now, UNIQLO's RFID reform is in full swing. Featured applications may refer to Fast Retailing's various brand stores in Yokohama, Japan, including RFID tags, fitting glasses, shopping carts, self-checkout and other intelligent devices.

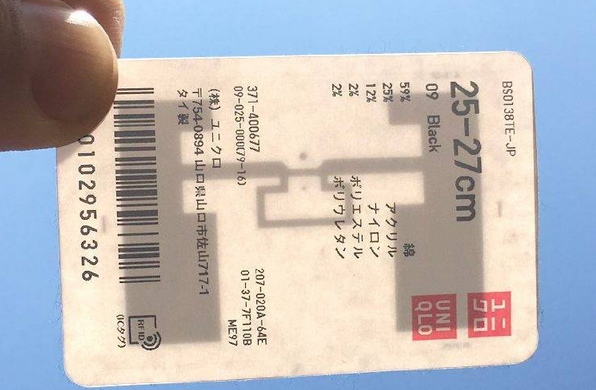

01. UNIQLO RFID tag

The UHF RFID tag is embedded in the RFID tag of Uniqlo. Based on the size difference, Uniqlo uses a variety of UHF tags, and only three forms are listed here.

In order to attract customers' attention to RFID, Uniqlo also made a small prompt on the RFID tag. Undoubtedly, this has greatly aroused the curiosity of customers and even triggered a big discussion among Uniqlo fans.

Some curious babies also disassembled the Uniqlo tag to find out.

In addition, Uniqlo will also introduce RFID high-energy equipment of sister brand GU - RFID fitting mirror and RFID shopping cart to deepen the RFID impression of fans.

02. GU RFID fitting mirror

The working mode of GU RFID fitting mirror is: the customer selects a piece of clothes and stands in front of the RFID fitting mirror. The RFID reading device embedded in the RFID fitting mirror identifies the RFID tag of the clothes, and displays various information of the clothes on the mirror, such as size, style, fabric, etc. At the same time, the screen will also display the pants, hats, sunglasses and other commodities that are suitable for matching this dress. These products have pre-stored information, and customers can click to query these products.

At the same time, customers can put their hands on their heads to check the buyer's comments, so as to help them judge the cost-effectiveness of clothes.

This RFID terminal equipment has greatly saved the cost burden of GU's hiring guide and reduced the total labor expenditure of GU.

03. GU RFID shopping cart

The sister brand GU of Uniqlo also innovated the RFID shopping cart, which is also a cool existence.

After customers select the clothes they are interested in, they can put the RFID tag on the RFID device in the shopping cart, and then the device will immediately display the product color, inventory status, and other dimensions.

Like the RFID fitting mirror, the shopping cart RFID device will also present the buyer's comments after sensing the RFID tag of the clothes. Customers can operate the terminal and look up and down at the buyer's comments, so as to obtain a more real, not just "model wearing" wearing experience, and determine whether to buy clothes.

For GU and Uniqlo, this has also greatly reduced the cost burden of shopping guides.

04. UNIQLO RFID self-checkout

Uniqlo launched RFID self-service checkout. After shopping, the customer places the clothes on the shopping cart on the RFID self-service checkout machine, which will scan and give the bill at one time. At that time, the customer can pay by swiping the code, and there is no manual service in the whole process. Compared with bar codes that require manual operation, RFID tags not only save the payment time of Uniqlo clothing, but also increase the production of hot products.

Many uniqlo fans have a great liking for the self-service settlement desk, believing that this settlement method greatly reduces their shopping time and improves shopping efficiency. For Uniqlo, this application reduces the labor cost of cashier and improves the accuracy of sales data, which is really killing two birds with one stone.In addition to reducing the labor burden at the levels of shopping guide, cash register and settlement, RFID also reduces the burden at the storage and data levels of Uniqlo.

05. RFID warehouse of Uniqlo

Under the trend of fast fashion, whether fashion can really "fast" or not is very important to the efficiency of logistics and warehousing operation. Especially for chain companies, once the efficiency of logistics system decreases, the operation of the whole company will suffer from risk impact. This is also considered when UNIQLO introduced RFID tags in the early stage.According to relevant reports, UNIQLO has pasted RFID tags on all products and combined them with automated material handling equipment. After the establishment of an automated warehouse, the number of warehouse personnel has been reduced from about 100 to 10, saving 90% of labor costs. At the same time, Uniqlo's production efficiency has increased by 80 times, the delivery productivity has increased by 19 times, the storage efficiency has increased by 3 times, the cost of personnel training has been reduced by 80%, and the accuracy of RFID automatic detection has been 100%.

In the 2018 Double 11 Shopping Carnival, Uniqlo achieved $1 billion in sales in one minute. And relying on its excellent automated inventory system, Uniqlo has realized that customers can pick up goods from offline stores within 24 hours.

06. RFID data processing of Uniqlo

The equipment in Uniqlo stores and logistics centers share a unified database. This database receives information automatically and indefinitely transmitted by RFID tags in real time, including inventory, quantity of goods sold, model, color, size and other goods information, and realizes real-time update of the inventory system. Therefore, when the product is sold out, the system will prompt Uniqlo staff to quickly replenish and produce. According to relevant data, with the support of RFID tags, Uniqlo's warehouse data processing time is only 10% of the previous time.

With UNIQLO's extensive deployment of FRID tags in 3000 stores around the world, Uniqlo may more easily and easily understand product-related information, such as volume, model and color, when consumers take the goods and put them back on the shelf, and when and where products are sold, so as to achieve rapid response from the production end to the sales end.