Application Of RFID Technology In Logistics Supply

- Share

- Issue Time

- Oct 6,2022

Summary

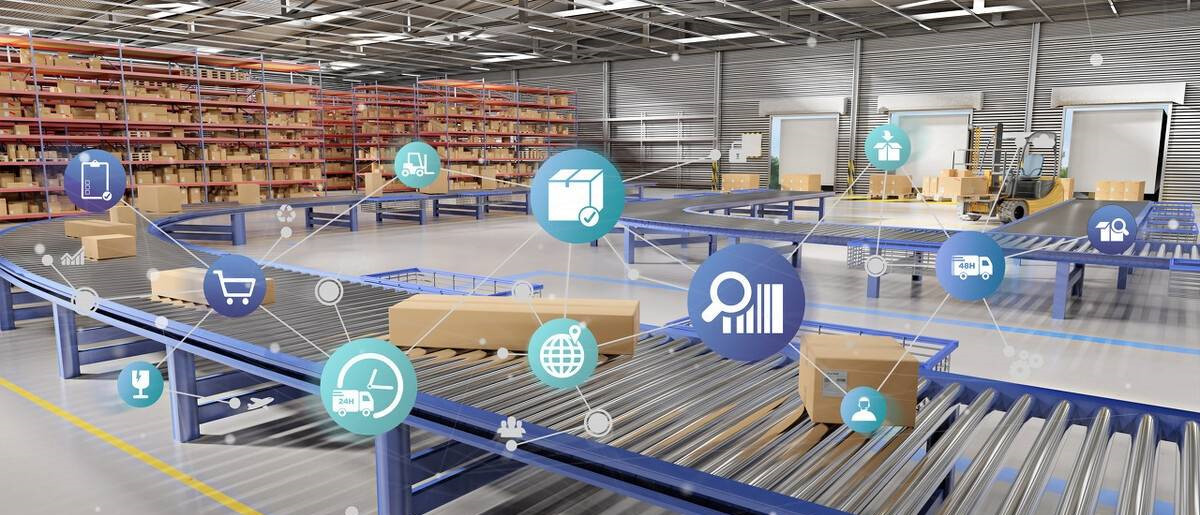

Because RFID technology has the characteristics of non-contact, long-distance and fast reading of multiple tags, its application in logistics supply chain scenarios can bring many benefits. It not only greatly improves work efficiency, but also opens a new window to digital information.

Radio Frequency Identification (RFID) technology, also known as Radio Frequency Identification (RFID), is a communication technology that can identify a specific target through Radio signals and read and write related data without establishing mechanical or optical contact between the Identification system and the specific target. The principle is to carry on the non-contact data communication between the reader and the tag to achieve the purpose of identifying the target. Because RFID technology has the characteristics of non-contact, long-distance and fast reading of multiple tags, its application in logistics supply chain scenarios can bring many benefits. It not only greatly improves work efficiency, but also opens a new window to digital information. The application of RFID technology in logistics supply chain can bring the following benefits.

1. Automatic operation

In real life, products are often transferred between multiple warehouses. After the use of RFID technology, the location of products can be determined when entering and leaving the warehouse, and then the products can be placed in a reasonable position in the warehouse to prepare for the next transportation. If the delivered product is delayed or sent to the wrong warehouse, it must be marked and restarted to the correct place in accordance with the requirements. All kinds of work above should be manually intervened, which will inevitably enhance the accuracy of the flow of the product supply chain and reduce the time spent on the flow.

2 Optimize the warehouse space

When RFID technology is used, the warehouse space application can be improved more rationally. Companies simply depend on the size and shape of their products and choose the most efficient way to store them. At the same time, warehouse managers can also use RFID handheld devices to determine the location of products, which can not only enhance the efficiency of positioning and packaging, but also reduce the time and energy spent by retailers for inventory.

3. Inventory minimization

After using RFID technology, we can know the inventory situation in real time, reduce the inventory level in the retail field in time, increase the pressure of each enterprise in the manufacturing and distribution field, and urgently need to meet the specific requirements of retailers in a short time. As a result, distributors will keep more and more buffer stock to meet their specific needs. Getting accurate new information improves the visibility of the supply chain and reduces the buffer stock size.

4. Ensure the safety of the transportation process and reduce the loss of goods

Theft and loss happened once will be a shortage of products, if in a retail environment most determined 1% loss rate can occupy the largest to the inventory of products, the loss is a big loss for profit, so it is necessary to reduce the data loss and theft, is its precision, guard against theft system can also be used as a retail environment.

5. Comprehensive product tracking capability

When tracking products in real time, it is important to improve customer service opportunities throughout the supply chain. Then realize the manufacturing and retail of products, fully understand the supply of goods to make a strategic decision. Now many logistics companies operate through the Internet services, such as the use of the Internet to track the operation of packages, so that they can gain a large number of market shares. This ensures that information is shared throughout the supply chain, which not only improves efficiency, but also increases customer loyalty.