RFID Railway Inspection and Repair Solution

- Share

- Issue Time

- Apr 25,2022

Summary

RFID is a non-contact wireless automatic identification technology, which effectively avoids missed inspection and re-inspection caused by human factors, realizes the preservation of inspection history data, provides reliable data for future maintenance, and ensures the normal operation of railway signal equipment.

- RFID (Radio Frequency Identification) is a non-contact wireless automatic identification technology, which realizes the transmission of energy through electromagnetic coupling in space, achieves the purpose of two-way communication and exchange of data, and realizes the automatic identification of objects to be identified. Combining RFID technology and single chip technology, a new type of wireless non-contact inspection instrument is designed, and a corresponding upper computer management system is designed to complete the functions of plan arrangement and inspection result preservation, effectively avoiding human factors. The missed inspection and re-inspection caused by the inspection can save the historical data of inspection, provide reliable data for future maintenance, and ensure the normal operation of railway signal equipment.

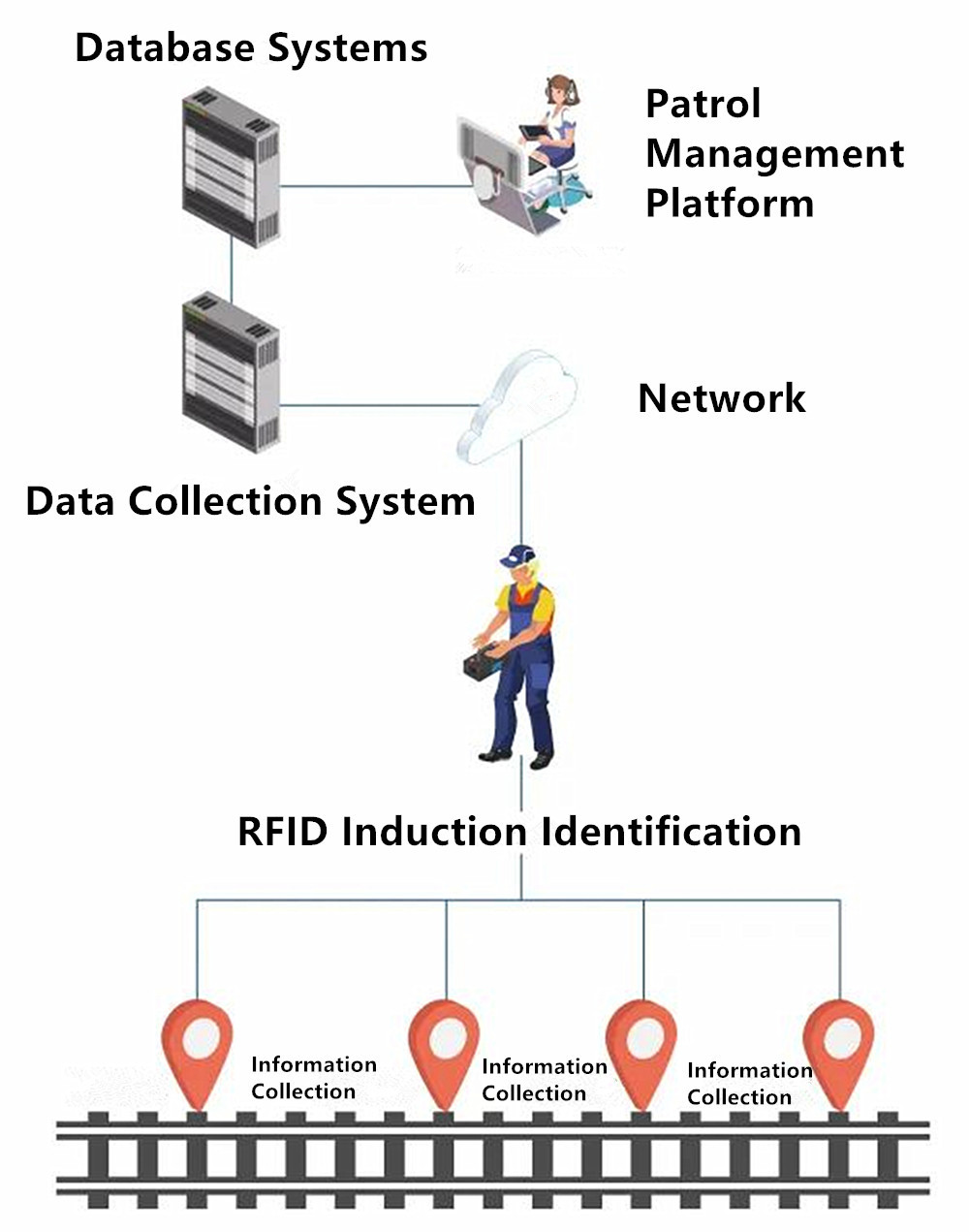

- The Overall Structure Of The Inspection System Of Railway Signal Equipment

- The inspection system includes RFID radio frequency inspection instrument, personnel information card, RFID equipment identification card, and inspection information management system. Before the inspection starts, the inspection personnel will place the inspection instrument close to the personnel information card to record the inspection personnel information. The inspection personnel arrive at the signal equipment maintenance site, place the inspection instrument close to the equipment identification card installed on the equipment, read the card number, and read the card again after the inspection is completed and the equipment running status is recorded. Prove the actual maintenance through the time interval between two card readings, and store the card number and inspection time in the FLASH memory. After the inspection is completed, upload it to the inspection management host, and the management software compares it with the generated plan to determine whether there is any missed inspection, and records the operation status of the inspected equipment to provide reliable data for future maintenance.

- The Hidden Dangers Of The Current Enterprise Inspection

- Railway signal equipment is a key facility for directing train operation, ensuring running safety, improving transportation efficiency, improving the way of running trains, and realizing the modernization of running command. In order to reduce failures, patrol signal workers must regularly inspect various signal equipment to discover and eliminate hidden dangers in time. The traditional inspection management of signal equipment generally adopts the method of sign-in, the records are easy to be forged, and the historical records are not easy to save, which is not convenient for statistical analysis. In order to improve the quality of inspection, an advanced RFID electronic inspection system must be introduced.