RFID Identification Application Modern Logistics Parcel Face List

- Share

- Issue Time

- Apr 6,2022

Summary

The use of RFID technology has become the main technical means of intelligent identification of modern logistics. Accurate, efficient and reliable identification of parcels, goods and commodities is an important basis for modern logistics intelligence.

- With the development of digitalization, the logistics industry has begun to pay more attention to the improvement of efficiency, the reduction of costs and the improvement of service quality. As the foundation and an important part of the realization of smart logistics, smart logistics guarantees the development and upgrading of smart logistics from the technical level. The entire logistics industry chain is undergoing intelligent and unmanned innovation. The coordinated operation of logistics technology represented by intelligent warehousing, logistics autonomous driving, and logistics drones promotes the efficient operation of the logistics network.

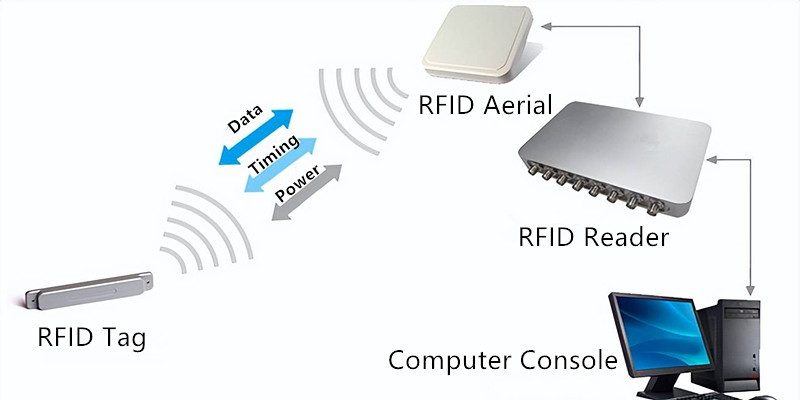

- RFID System Principle

Under the demand of logistics intelligence, accurate, efficient and reliable identification of parcels, goods and commodities is an important basis for modern logistics intelligence. The use of RFID technology has become the main technical means of intelligent identification of modern logistics.

- The application of RFID in logistics is divided into two main types of mainstream application scenarios according to different business forms, express parcel logistics and e-commerce warehousing logistics. In the two most representative logistics formats of RFID application, the back-end sorting, transportation, distribution and other business processes are basically the same.while the front-end of e-commerce warehousing and logistics consists of “order-receiving-warehouse picking-sorting-transportation”, and e-commerce warehousing has more prominent needs in warehouse intelligent inventory, automatic identification of inbound and outbound warehouses, and verification.

- As the most commonly used and hugely used package identification, RFID technology is used to greatly improve the overall sorting efficiency. In the automatic identification requirements of intelligent logistics, the core requirements of logistics enterprises for RFID are ultra-low cost and high identification accuracy. According to the survey, most express logistics companies are willing to fully adopt RFID technology for package management, sorting, warehousing and tracking when the price of the RFID surface order is less than 0.1 yuan. The core of efficient identification of express parcels in logistics is sorting and identification. The efficiency of logistics enterprises has increased, the high-speed sorting lines have become faster and faster, the line speed has been continuously improved from 2 m/s to 6 m/s, and the package spacing has been reduced from 50 cm to 30 cm, or even 15 cm. The requirements for precision are also getting higher and higher.

- At present, the linear speed of the small bag sorting belt balance wheel of the logistics enterprise is 2 meters to 3 meters per second. If the average linear speed is 2.5 meters per second, the width of the RFID radio frequency identification area is 1000 mm, and a single label passes through the identification area. The time is 400 milliseconds. 400 milliseconds seems to have no difficulty in identifying a single RFID. However, the identification system needs to complete the identification of all kinds of packages with electronic face sheets (including textiles, books, electronic devices, metals, liquids, food...) during this period, and the positions of the face sheets on the package are also different. , wrapping the front, end, bottom, side and other positions.

- The regular package spacing is 500mm, and most of the small packages have an average of 300mm to 500mm on the longest side, which is calculated according to the label attached to the center of the package. That is to say, the spacing between the tags is evenly distributed at 900 mm, and the time difference between the front and rear tags is about 500 milliseconds. For a conventional RFID system, it is not too difficult to distinguish the order of the front and back tags within 500 milliseconds.

- Then, with the faster line speed (4 meters per second), the smaller the package spacing (300 mm), the less time is left for the RFID system to collect and calculate, and the time interval for the front and rear packages to enter the RF field strength will become 175 milliseconds, which is just the norm. When the front and rear wrapped labels are face to face (minimum label spacing of 300mm), the front and rear entry field strength times are only 75 milliseconds. This poses a higher challenge to the data read frequency of the RFID acquisition system. The system also needs to deal with various complex situations including the passage of one package with multiple labels, the passing of empty packages (without labels), the passing of one consecutive package with multiple labels, and the passing of consecutive empty packages.

- As a booming modern logistics system, e-commerce warehousing logistics has similar requirements for automatic identification as express parcels. In addition to sorting requirements, it pays more attention to automatic and efficient identification of post-sorting verification (pallets, cages) and loading verification. For this reason, the market requires RFID tags to have extremely high sensitivity, and also requires RFID tags to have more stable reading performance in all directions when passing through the collection device, which is what we often call "omnidirectional tags". The reader requires higher frequency identification and data collection capabilities to provide enough data samples to judge the order of the packages and the abnormality of the packages.

- The technological progress of the RFID industry has prepared for the intelligence of modern logistics. Let's wait and see logistics as the next huge market after RFID clothing application.