Application Of RFID In The Footwear And Apparel Industry

- Share

- Issue Time

- Mar 16,2022

Summary

Through the comparison of barcode technology and RFID technology, it can be seen that RFID technology has the characteristics of long-distance reading, high storage capacity, reusability, strong penetration and long service life. The core technology of a new generation of store management, and help the long-term sustainable development of the industry.

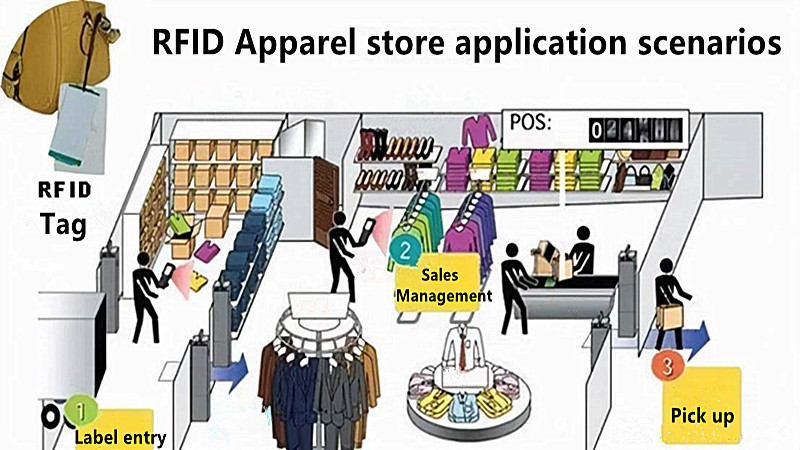

- RFID technology in the clothing retail industry is mainly used in three links, namely logistics supply chain, store operation, and warehouse management. In the initial stage of the logistics supply chain, enterprises can consider how to apply RFID electronic tags to clothing according to their own costs. There are two common methods on the market, one is to sew in the way of washing labels, and the other is to use clothing hang tags. exist. No matter how it exists, the RFID electronic tag, which is the most basic part of the RFID solution, will become a consumable item along with the apparel fast-moving consumer goods. Therefore, the amount of RFID electronic tags serving apparel products is continuous and huge.

- In the logistics and transportation stage, the traditional logistics supply chain system has low efficiency and high logistics cost. Due to the inability to obtain comprehensive cargo transportation information, the information in each link of the supply chain is not smooth, and the information formed in the supply chain system is incomplete. The information that the enterprise has learned includes: There may be delays or inaccuracy with the information required by customers. An efficient and low-cost supply chain requires companies to respond quickly and effectively to customer needs and be prepared to deal with various uncertainties in the supply chain.

- Using RFID technology, we can grasp the first-hand supply chain data information, and timely and effectively follow up customer demand changes in the supply chain. Enterprises can use RFID electronic tags and PDA smart mobile terminals to collect product inbound and outbound data when products leave the warehouse and arrive at sales stores, and track the transportation status in real time in the software background to obtain transportation information. For example, when did this batch of goods leave the warehouse, when it was put into the warehouse, where has it been delivered, whether it can be delivered on time, whether there is an unexplained condition, whether there are products specified by the customer or want to exchange in the goods, etc.

- In store operation, RFID technology can help sales staff quickly find specified products, provide decision-making analysis for merchants, and enhance customer consumption experience. If the customer wants a product, it may take 5-10 minutes for the salesperson to find the specified product in a large number of products by conventional methods; after using RFID technology, the salesperson can use the UHF RFID handheld device according to the customer's description. Product model, code, etc., automatically search for the RFID tag signal connected to the product in a certain area, so as to quickly find the corresponding product.

- In addition, by detecting the number of times and the length of time that the products on the shelves are taken, and installing smart fitting mirrors, smart "magic mirrors", etc., merchants can also learn the data information of the products' best-selling, slow-selling and customer preferences, so as to provide information for product display and Product purchasing decisions provide data support, and at the same time bring new consumption experiences to customers.

- In terms of warehouse management, RFID technology can control the real-time data of goods in and out of warehouses and inventory counts. For example, after a clothing retailer receives a receipt notice in an inventory center, the RFID warehouse management system selects the corresponding warehouse according to the batch of goods, and automatically allocates warehouse areas and locations. After the goods arrive in the waiting area, the RFID reading and writing equipment at the channel of the warehouse area can read the goods label at one time. After the read data is checked with the data on the notice, the goods can be stored in the storage location allocated by the system. , and the system will also form a detailed receipt according to the goods receipt date, category, quantity and other information.

- Through the comparison of barcode technology and RFID technology, it can be seen that RFID technology has the characteristics of long-distance reading, high storage capacity, reusability, strong penetration and long service life. The core technology of a new generation of store management, and help the long-term sustainable development of the industry. At present, many apparel brand retailers such as Uniqlo, Heilan Home, Decathlon, ZARA, Nike have successfully introduced RFID projects, and the results are very good.